Welcome to our comprehensive guide on hydraulic die separator repair and refurbishment. At American Electric Motors, we understand the critical role hydraulic die separators play in various industries, enabling efficient disassembly and reassembly of dies and molds. Over time, these essential pieces of equipment may experience wear and tear, affecting their performance and efficiency. In this article, we will explore the importance of repairing and refurbishing hydraulic die separators, highlighting the benefits and steps involved in the process.

The Significance of Hydraulic Die Separator Repair and Refurbishment

Hydraulic die separators are relied upon by industries that work with dies and molds, such as manufacturing, metal fabrication, automotive, and more. These devices enable precision separation of complex die components, ensuring smooth maintenance, repair, and reconditioning processes. However, regular usage and continuous operation can lead to wear, component fatigue, and decreased performance.

Repairing and refurbishing hydraulic die separators is a proactive approach to maintaining the equipment’s functionality and extending its lifespan. It offers several advantages, including:

1. Enhanced Performance and Efficiency

Through the repair and refurbishment process, hydraulic die separators regain their original performance capabilities. Worn-out or damaged components are replaced, and critical parts are restored to their optimal condition. This results in improved efficiency, precise separation, and increased productivity during die maintenance and reassembly operations.

2. Cost Savings

Repairing and refurbishing a hydraulic die separator is a cost-effective alternative to purchasing a new unit. By addressing specific issues and replacing only the necessary components, you can save on significant investment costs. It allows you to allocate your resources wisely while still maintaining the functionality of your equipment.

3. Extended Lifespan and Reliability

Hydraulic die separators that undergo regular repair and refurbishment can have their lifespan significantly extended. The process ensures that all components are inspected, repaired, or replaced as needed, preventing further damage and potential breakdowns. With proper maintenance and periodic refurbishment, your hydraulic die separator will continue to deliver reliable performance for years to come.

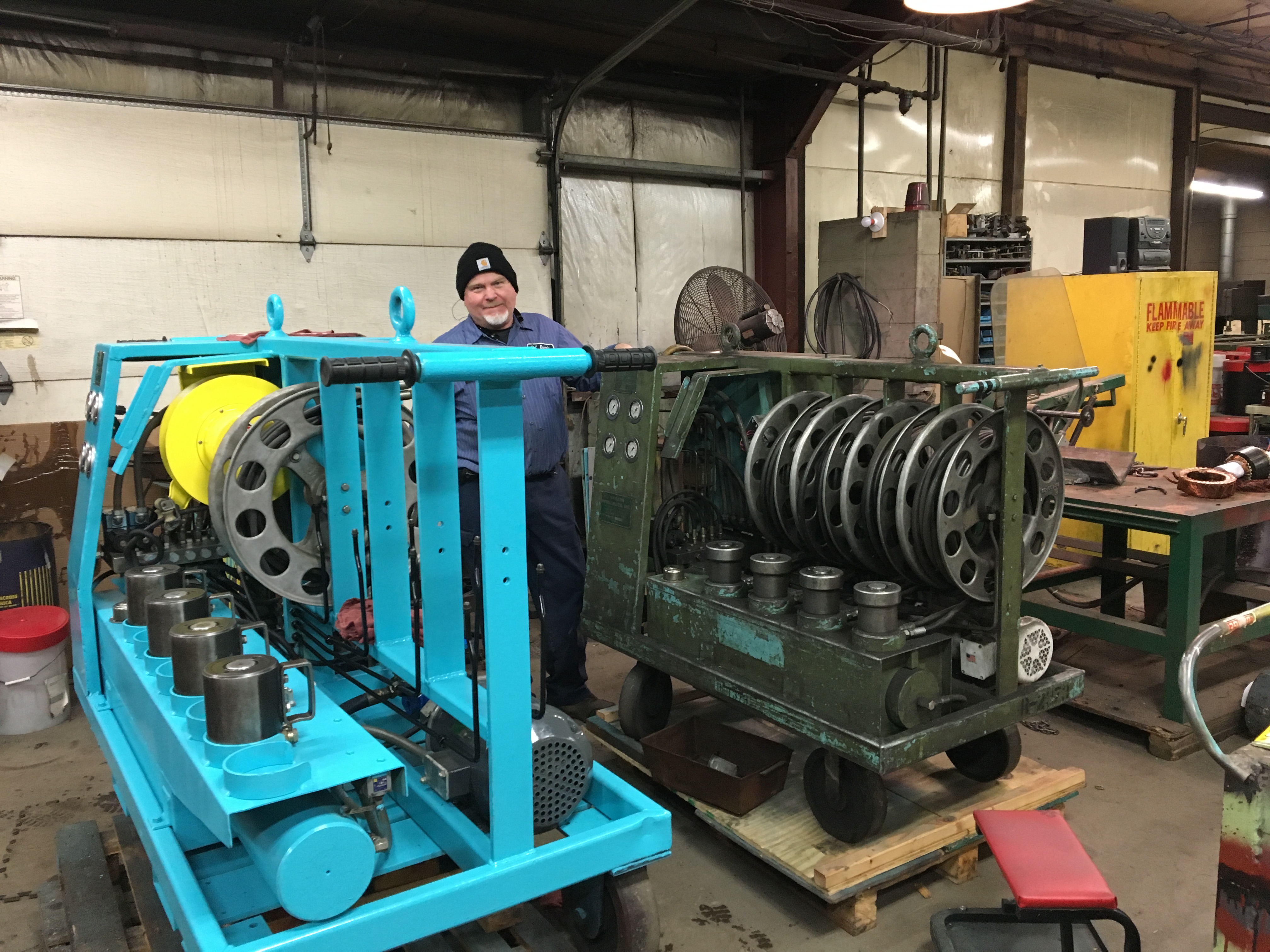

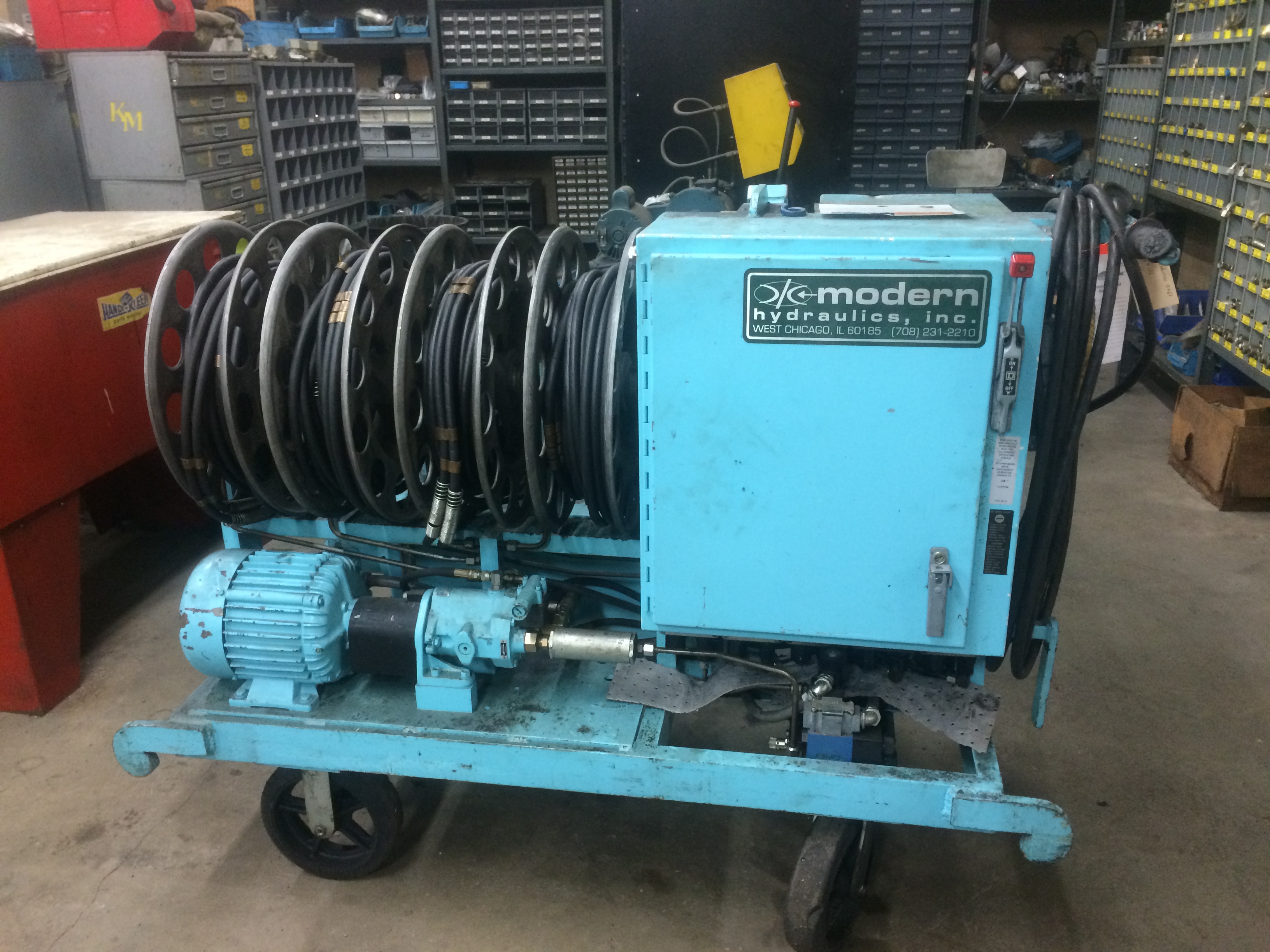

The Hydraulic Die Separator Repair and Refurbishment Process

At American Electric Motors, we follow a systematic approach to repair and refurbish hydraulic die separators, ensuring the highest level of quality and reliability. Here are the key steps involved in the process:

1. Initial Assessment and Evaluation

Our experienced technicians begin by conducting a thorough assessment of your hydraulic die separator. They examine the equipment’s condition, performance, and any specific concerns you may have. This evaluation allows us to develop a tailored repair and refurbishment plan that addresses your unique requirements.

2. Component Inspection and Replacement

During the inspection phase, our technicians carefully examine all the components of the hydraulic die separator. They identify worn-out or damaged parts, including seals, cylinders, valves, and hydraulic lines. Based on their findings, they determine which components need to be repaired or replaced.

3. Cleaning and Lubrication

Before proceeding with repairs, the hydraulic die separator is thoroughly cleaned to remove dirt, debris, and contaminants that may affect its performance. Special attention is given to critical areas where proper lubrication is crucial for smooth operation. Clean components and proper lubrication are essential for optimal functionality and longevity.

4. Component Repair or Replacement

Based on the inspection results, our technicians perform necessary repairs or replacements on the identified components. Worn-out seals and gaskets are replaced, hydraulic lines are repaired, and valves are restored to their original condition. We use high-quality parts to ensure the longevity and reliability of your hydraulic die separator.

5. Calibration and Testing

After the repair and replacement process, we calibrate the hydraulic die separator to ensure its proper functioning. Our technicians meticulously adjust the pressure, flow, and other critical settings to meet the manufacturer’s specifications. Additionally, a series of tests are conducted to verify the equipment’s performance, ensuring it operates at its optimal level.

6. Preventive Maintenance Recommendations

As part of our comprehensive service, we provide preventive maintenance recommendations to help you keep your hydraulic die separator in top condition. Our experts will advise you on best practices, routine inspections, lubrication schedules, and any specific maintenance tasks to perform regularly. Following these recommendations will minimize the risk of future breakdowns and maximize the equipment’s lifespan.

Trust American Electric Motors for Hydraulic Die Separator Repair and Refurbishment

At American Electric Motors, we specialize in the repair and refurbishment of hydraulic die separators. With our expertise, state-of-the-art facilities, and commitment to quality, we ensure that your equipment receives the attention it deserves. Our goal is to deliver reliable, efficient, and long-lasting solutions that meet your specific needs and exceed your expectations.

Contact us today to discuss your hydraulic die separator repair and refurbishment requirements. Our team of skilled technicians is ready to provide you with a personalized solution that will extend the lifespan of your equipment, enhance its performance, and optimize your operational efficiency.